Sample preparation for TEM requires thinning the sample so far that it becomes transparent to the electron beam. Mechanical sample thinning must use techniques to avoid deformation of the sample. Mechanical thinning is also used prior to ion-beam thinning for cross sectional samples. For mechanical sample preparation for TEM samples (and in some cases small SEM samples), the following tools and instruments are offered:

- Microsaw MS3 for precise cutting of hard materials

- Micropol MC3 for precise polishing of TEM samples

- Microheat MH4 for thermoplastic bonding of samples

- X-TEM full sample preparation kit with Microsaw MS3, Micropol MC3 and Microheat MH4

- X-TEM HSS hand-tools kit for sample preparation

- X-TEM titanium embedding discs and consumables for TEM sample preparation

All instruments are supplied with universal voltage: 100-240V / 50-60Hz.

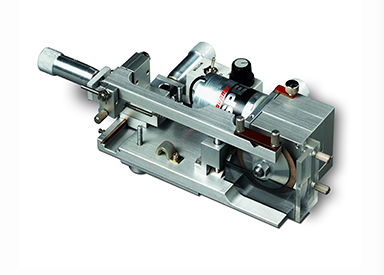

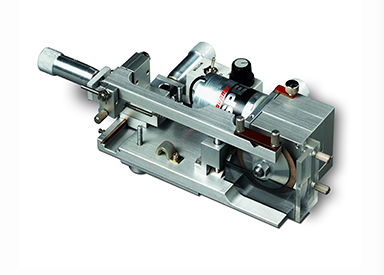

Microsaw MS3 for precise cutting of sample under a stereo microscope

The Microsaw MS3 is a compact versatile diamond wheel which can be easily mounted under a stereo microscopes due to is small size. It is especially designed for cutting and sectioning as required during TEM sample preparation of solid and hard materials. The Microsaw MS3 comprises a precise helical drive train with reduced backlash to ensure precise and reproducible sectioning with 0.01mm accuracy. The cutting speed of the diamond wheel is continuously adjustable. The specimen is mounted on the arm with adjustable tension, arm contact point and integrated down-stop control mechanism. Supplied with diamond wheel. Adjustable feet for levelling. The diamond cutting wheel runs in a reservoir for coolant.

- Precise cutting with low deformation

- Compact; fits under a stereo microscope

- Easy and quick to use

| Sample size | Max. 10 x10mm |

| Minimum slice thickness | 0.01mm |

| Maximum sample size (LxWxH) | ~ 10 x 10 x 2mm |

| Speed range | 35 – 410 rpm |

| Diamond wheel dimensions | Ø50 x 0.15mm |

| Diamond wheel type | AC32 with 63/50um grit |

| Motor power | 12V DC / 1.5A / 18W |

| Power input | 100-240V / 50-60Hz |

| Dimensions | 260 x 150 x 80mm |

| Microsaw MS3 incl. diamond cutting blade, 100-240V / 50-60Hz |

|---|

| Product # | Unit |

| 29-001100 | each |

| Diamond cutting blade, for Microsaw MS3, Ø50 x 0.15mm, 63/50 grit |

|---|

| Product # | Unit |

| 29-001110 | each |

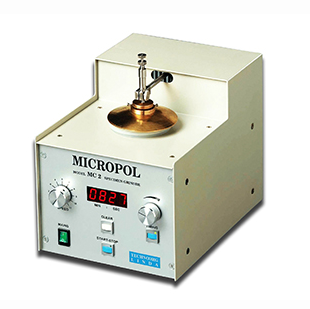

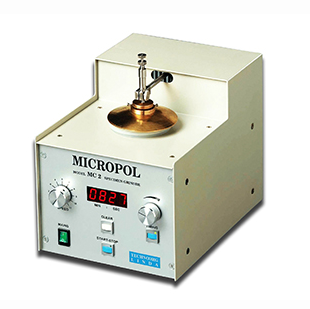

Micropol MC3 for precise grinding, polishing or dimpling of TEM samples

The Micropol MC3 polisher is a compact, electrically controlled, precise mechanical sample grinder/polisher designed for planar grinding, dimpling, thinning and polishing of TEM samples. The polishing parameters (speed, load, time) can be adjusted according to the requirements of the specific specimens and materials. High quality samples are prepared with minimal efforts. The arm of the Micropol MC3 moves the specimen in a semi-random geometric pattern, pressing it gently to the polishing bowl which contains suitable abrasive material. The abrasive materials can be grinding paper or suspensions of polishing compound on a polishing cloth. This versatile instrument is supplied with flat polishing discs and specimen holder for planar samples and with spherical bowls and specimen holder for dimpled samples. The bowls can be rapidly changed using the quick exchange bayonet mounts. The Micropol MC 3 is supplied with a selection of bowls and consumable starter kit (Ø44mm abrasive papers 240 & 400 grit, polishing cloth, diamond paste 1 & 10um and thermoplastic wax). Thickness measuring kit included.

- Versatile polishing and dimpling instrument

- Variable speed control for precision polishing

- Timer for automatic operation

- Extremely light load for fragile TEM samples

- Corrosion proof, rugged construction

| Sample size | Ø10 – 15mm |

| Moving mass | 150g max. |

| Moving speed of the arm | 30 – 60 scans/min |

| Load | 0 – 5N |

| Timer | 1 – 3600 seconds |

| Specimen holders | 2 |

| Flat polishing bowls | 4 |

| Spherical dimpling bowls | 4 |

| Thickness measuring kit | included |

| Power consumption | 85W |

| Power supply | 100-240V / 50-60Hz |

| Dimensions | 251 x 220 x 181mm |

| Micropol MC3 polishing / dimpling system, incl. bowls and starter kit, 100-240V / 50-60Hz |

|---|

| Product # | Unit |

| 29-001200 | each |

| Consumable package for Micropol MC3 incl. 20 ea 600 & 1200 grit grinding paper, 2 ea polishing cloths, 20g ea diamond paste 1 & 10µm and 1 stick of mounting wax MW135 |

|---|

| Product # | Unit |

| 29-001210 | each |

Microheat MH4 for thermoplastic bonding of samples

The Microheat MH4 is a compact, heat stabilized hot plate especially designed for embedding samples and for thermoplastic gluing under the stereo microscope. The compact and low profile unit can be easily placed under a stereo microscope to enable bubble free embedding and gluing which is important for cross-sectional samples for electron microscopy. The temperature of the hot plate can be adjusted over a wide range and is electronically kept at the adjusted level within ± 5°C. The actual temperature is shown on the LCD display of the Microheat MH4. Desired temperature is usually reached within 1-3 minutes.

- Heat-stabilized

- Compact low profile

- Ideal for thermoplastic gluing

| Temperature range | 50 – 150°C. |

| Power consumption | 12V DC / 1.2A / 14W |

| Power input | 100-240V / 50-60Hz |

| Dimensions | 100 x 100 x 30mm |

| Microheat MH4 system, 100-240V / 50-60Hz |

|---|

| Product # | Unit |

| 29-001300 | each |

X-TEM full sample preparation kit with Microsaw MS3, Micropol MC3 and Microheat MH4

The complete X-TEM sample preparation kit includes the Microsaw MS3, the Micropol MC3, the Microheat MH4, 5 sizes of Titanium embedding rings, the HSS hand-tools kit, AT1 ion-beam resistant glue, conductive carbon cement, MW transparent glue and diamond pastes for 1 and 10um.

| X-TEM full sample preparation kit for TEM sectioning, 100-240V / 50-60Hz incl. Microsaw, Micropol, Microheat, tools and consumables kit |

|---|

| Product # | Unit |

| 29-001500 | each |

| Consumable package for Micropol MC3 incl. 20 ea 600 & 1200 grit grinding paper, 2 ea polishing cloths, 20g ea diamond paste 1 & 10µm and 1 stick of mounting wax MW135 |

|---|

| Product # | Unit |

| 29-001210 | each |

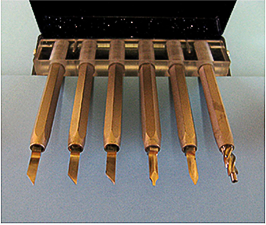

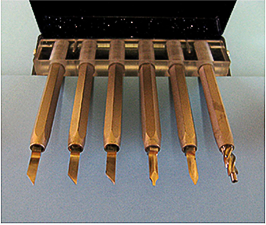

X-TEM HSS hand-tools kit for TEM sectioning sample preparation

Mechanical sample preparation prior to thinning usually requires special mechanical hand tools. The X-TEM HSS hand-tools kit contain six high quality, practical and reliable tools. The tools are designed for various tasks such as:

- Adjusting sample in the X-TEM Ti discs

- Removing of excess glue

- Cutting

- Adjusting the seat plate of the sample holder

| X-TEM HSS handtools kit for TEM sectioning sample preparation incl. 4 handtools |

|---|

| Product # | Unit |

| 29-001510 | each |

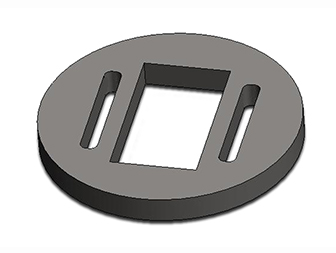

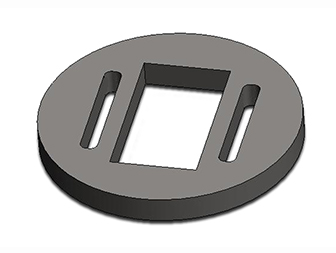

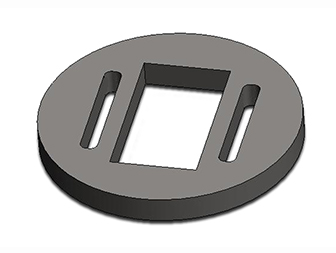

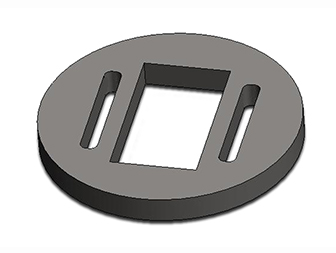

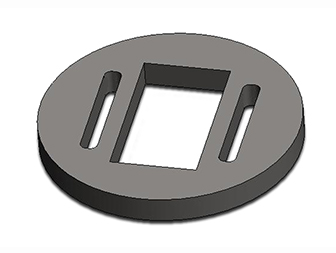

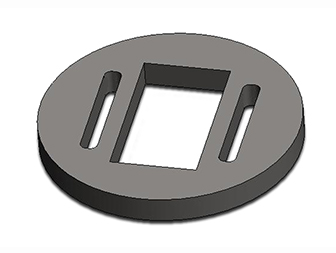

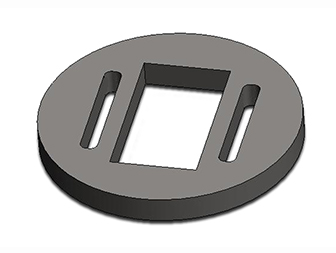

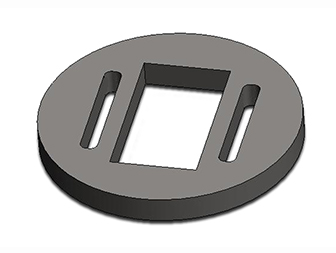

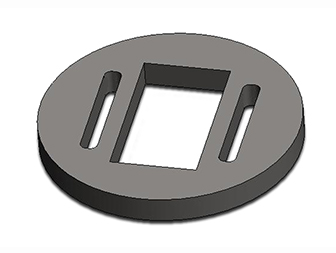

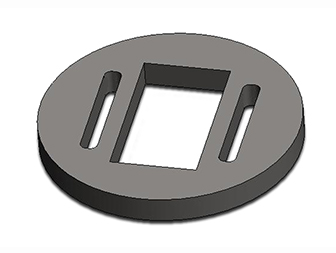

X-TEM titanium embedding discs and consumables for TEM sample preparation

The X-TEM titanium discs have been developed to simplify mechanical preparation of cross section TEM samples. With the Ø3mm X-TEM Ti discs, sample can be place in the cavity and are held by mechanically deforming the thin strips on both side of the hole. By using this method, the samples don’t need to be glued prior to embedding. The deformed strips both hold the sample in the disc and press sample pieces together before gluing. There is a range of hole openings available to accommodate sample pieces ranging from 0.6 to 1.3mm. The advantages of Titanium based disc based encapsulation technology are:

- Low sputtering rate, excellent sample protection parameters

- Low level of implantation into the encapsulated samples

- Emission of blue light during ion beam treatment gives instant optical feedback

- Excellent mechanical properties

- Good machining properties

| Material | Titanium |

| Diameter | 3mm |

| Thickness | 0.3mm |

| Hole dimension width | 0.6, 0.8, 1.0. 1.2 1.3mm |

| Hole dimension length | 1.8mm |

| EM-Tec C38 strong conductive carbon cement, 25g bottle |

|---|

| Product # | Unit |

| 15-001138 | each |

| Micro-Tec DP1 oil based diamond polishing paste, 1µm, yellow colour, 5g syringe |

|---|

| Product # | Unit |

| 29-001580 | each |

| Micro-Tec DP10 oil based diamond polishing paste, 10µm, light green colour, 5g syringe |

|---|

| Product # | Unit |

| 29-001590 | each |

| Ti sample holder disc, Ø3×0.3mm, 0.6×1.8mm hole |

|---|

| Product # | Unit |

| 29-001520 | each |

| Ti sample holder disc, Ø3×0.3mm, 0.8×1.8mm hole |

|---|

| Product # | Unit |

| 29-001530 | each |

| Ti sample holder disc, Ø3×0.3mm, 1.0×1.8mm hole |

|---|

| Product # | Unit |

| 29-001540 | each |

| Ti sample holder disc, Ø3×0.3mm, 1.2×1.8mm hole |

|---|

| Product # | Unit |

| 29-001550 | each |

| Ti sample holder disc, Ø3×0.3mm, 1.3×1.8mm hole |

|---|

| Product # | Unit |

| 29-001560 | each |

| AT1 Ion beam resistant glue (Araldite with carbon powder), 20ml |

|---|

| Product # | Unit |

| 29-001570 | each |

| MC-SHB3 Hand polisher with ceramic inserts |

|---|

| Product # | Unit |

| 29-001610 | each |